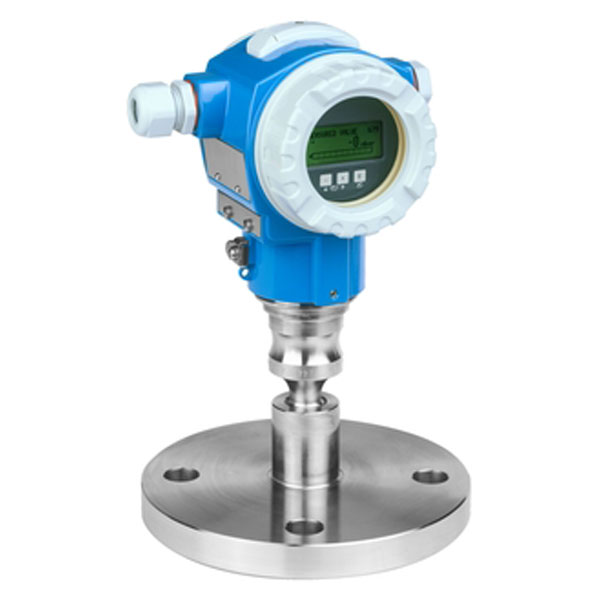

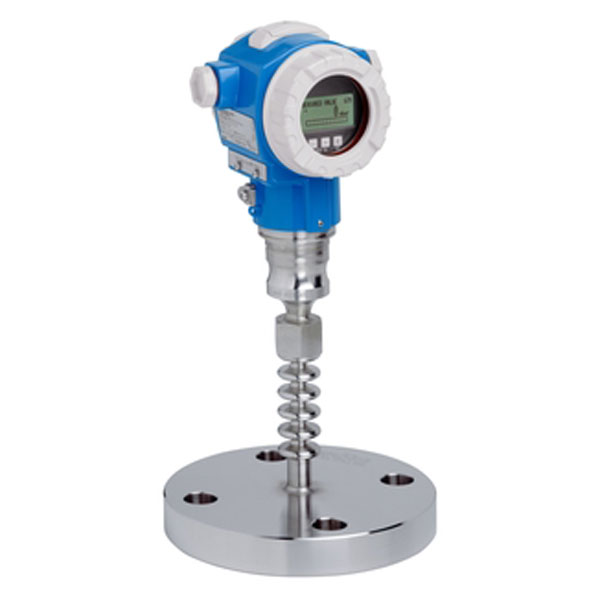

Description

Digital pressure transmitter with fully welded chemical seal for measurement in gases or liquids.

Pressure device for measuring pressure in industrial and non-industrial environments in process temperatures up to 400°C. The sensor element has an optimised mechanical construction to reduce the temperature effect of the chemical seal.

Highlights

- Temperatures up to 400°C

- Self-diagnosis and process monitoring functions

- Standard 0.05% linearity and chemical seal error

- IEC61508 up to SIL3

Advantages

- Optimised for chemical seal mounting

- Long-term stability <0.05% PER 5year minimises recalibration

- HART, PROFIBUS and FOUNDATION Fieldbus compatible

- Menu-guided display with plain text – no error codes to decipher

- No software or handheld communicators required

- Available with TempC membrane for improved accuracy and process safety in difficult pressure and DP applications

Technical Data

| Measuring Range | 100 mbar…400 bar gauge or absolute/TD 100:1 (larger TD on request) |

| Process Temperature | -70°C…400°C |

| Ambient Temperature | -40°C…85°C |

| Protection class | IP67 (IP68 optional) |

| Power Supply | 10.5…45V DC standard, 10.5…30V DC for EExi 9…32V DC for PA and FF |

| Cable connection | Gland M20x1.5, ½” NPT, 7 /8” FOUNDATION Fieldbus connector, M12 |

| Accuracy | 0.05% (transmitter) + chemical seal error |

| Housing cast | Aluminium with polyester based coating, (stainless steel 316L optional) |

| Process connection | All standard DIN/ANSI pressure and hygienic process connections |

| Process seal | Welded construction with secondary containment |

| Process membrane | 316L (1.4435), Alloy C276, Monel, Tantalum, PTFE foil, TempC, etc. Fill fluid silicon oil, vegetable oil (FDA), inert oil, high temperature oil etc. |

For more information, specific application advice or to order,

Please Contact us on +91 8367005552 or +91 9063008734

email: info@sigmaautomation.co.in or instsales@sigmaautomation.co.in

Technical Information for Cerabar S PMC71, PMP71, PMP75