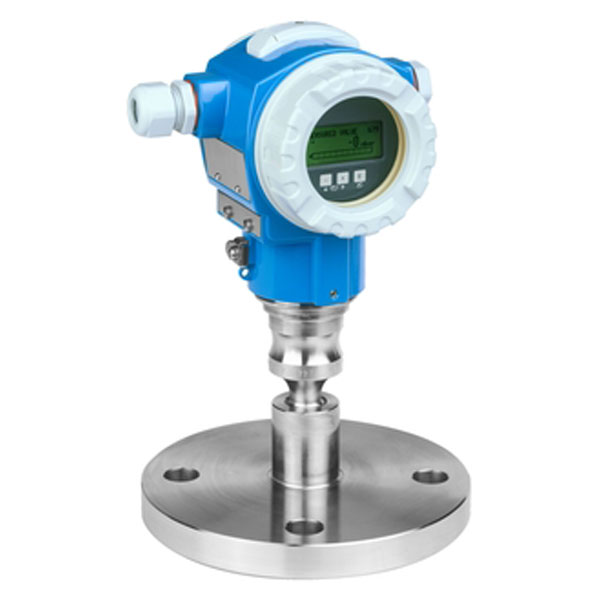

Description

For functional safety applications requiring a high degree of failure safety and availability. Used for safety-critical systems up to SIL3 in the chemicals, petrochemicals and oil & gas industries.

The Liquiphant FailSafe point level switch offers Safety Integrity Levels up to SIL3 with a single instrument requiring a high degree of failure safety and availability. The high SIL rating is achieved by dual redundancy and permanent self-monitoring of the instrument. In addition, a constant live signal monitors vital functions. Another benefit is the significantly simplified proof test according to IEC 61508/IEC 61511 functional safety requirements. Downstream devices in the safety loop such as valves are checked by simply pressing a button at the sensor or switching unit – saving both time and money.

Liquiphant FailSafe FTL80, FTL81 and FTL85 are available with a variety of coatings to cope with even highly corrosive media. Additional options provide a special design and materials to allow the sensor to resist process temperatures of up to 280°C. Liquiphant FailSafe can either be directly integrated into a (safety) PLC via a 4-20mA interface or can be installed with the Nivotester FailSafe FTL825.

Technical Data

| Process temperature | Between -60°C… +280ºC |

| Process pressure | -1 bar… 100 bar |

| Product density | > 0.4g/cm3 |

| Viscosity | < 10,000mm2 /s (cSt) |

| Sensor material | Stainless steel, Hastelloy or coated |

| Process connections | Thread or flange |

| Housing material | Polyester, stainless steel or aluminium |

| Degree of protection | IP66, IP67, IP68/NEMA 4X/6P (depending on housing) |

| Certificates | ATEX, IEC Ex, FM, NEPSI |

For more information, specific application advice or to order,

Please Contact us on +91 8367005552 or +91 9063008734

email: info@sigmaautomation.co.in or instsales@sigmaautomation.co.in

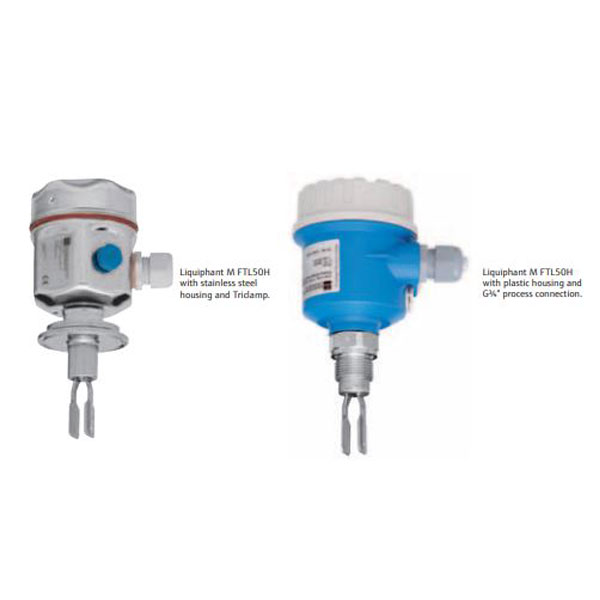

Technical Information

FTL80/81/85

FTL825