Description

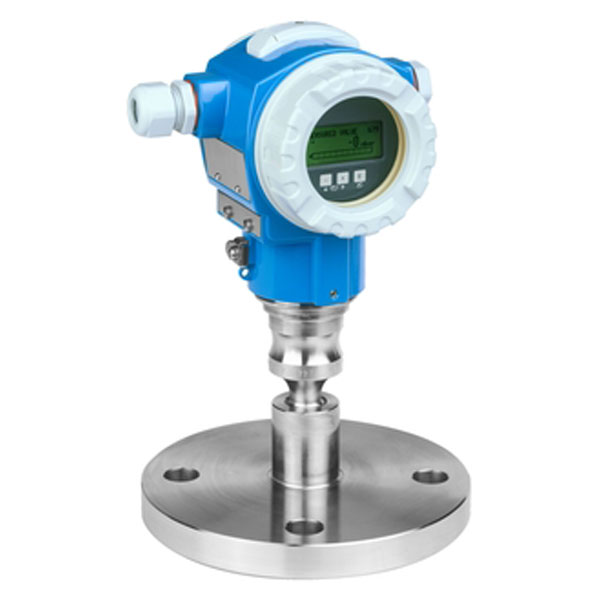

Differential Pressure Transmitter for flow, level and filter applications.

This is a high-performance differential pressure transmitter based on piezoresistive working principle. It uses a piezoresistive sensor that is built on a diaphragm to sense the pressure. This device is suitable for use in industrial process applications, with a high accuracy and high stability. It can handle high pressure and temperature, and it offers a variety of output signals such as 4-20mA and Hart protocol.

Before Discussing about Piezoresistive Pressure Transmitter and Capacitance Pressure Transmitter , we will see what is the key difference between Both Type.

Piezoresistive and capacitance sensors are both types of pressure sensors that are used to measure pressure in various applications, but they work on different physical principles and have some key differences.

Piezoresistive sensors, as explained earlier, use the piezoresistive effect, which is the change in electrical resistance that occurs in certain materials when a mechanical stress is applied. This effect is based on the deformation of a semiconductor material, typically silicon, due to the applied pressure, which results in a change of resistance of the material.

On the other hand, capacitance sensors use the principle of capacitance, which is the ability of a material to store electrical charge. In a capacitance pressure sensor, a diaphragm is used as a fixed electrode, and a second electrode is placed in close proximity to it. As the pressure changes, the diaphragm deflects, which changes the distance between the two electrodes, and in turn, changes the capacitance between them. This change in capacitance is then used to measure the pressure.

Here are a few key differences between the two types of sensors:

•Piezoresistive sensors are typically more accurate and linear, but also more sensitive to temperature changes.

•Capacitance sensors are less sensitive to temperature changes, and also more stable over time, but typically less accurate than piezoresistive sensors.

•Piezoresistive sensors are typically less expensive than capacitance sensors.

•Capacitance sensors are less affected by electromagnetic interference(EMI) than piezoresistive sensors.

b)Capacitance Based Pressure Transmitter .

• PMC71B: This model is suitable for applications that require a high level of accuracy and stability, and for harsh industrial environments that require a remote diaphragm seal for protection from corrosive and abrasive process media, such as chemical and petrochemical processes, power plants and oil & gas industries.

• PMC51B: This model is suitable for applications that require a high level of accuracy and stability, but have less harsh conditions than PMC71B. Such as general industrial process, like water and sewage treatment plants, building automation, and HVAC systems

• PMC21: This model is suitable for applications that require a compact and cost-effective solution with a 4-20mA output signal and for situations where space is limited, such as in small, confined spaces in industrial equipment, or when the pressure measurement needs to be integrated into a smaller control system.

• PMC11: This model is similar to the PMC21 with different pressure range or output signal option.

PMC71B/PMC51B

PMC21/PMC11

Piezoresistive based Pressure Transmitter :

• PMP75: This model is suitable for high-pressure applications that require a high level of accuracy and stability, such as in the oil and gas industry, in drilling and production operations, or in high-pressure process control systems.

• PMP71B: This model is suitable for harsh industrial environments that require a high level of accuracy, stability and repeatability, such as chemical and petrochemical processes, power plants, and oil & gas industries.

• PMP55: This model might be suitable for general industrial process applications that require high accuracy, stability and repeatability, such as water and sewage treatment plants, HVAC systems, building automation and process control systems.

• PMP51B: This model is suitable for industrial process control applications that require a high level of accuracy, stability and repeatability, but with less harsh conditions than PMP55. like in food and beverage industry, pharmaceutical, and cosmetics applications.

• PMP23: This model might be suitable for applications that require a compact, low-cost solution with a 4-20mA output signal, and for situations where space is limited, such as in small, confined spaces in industrial equipment, or when the pressure measurement needs to be integrated into a smaller control system.

• PMP21: This model might be suitable for applications that require a high-accuracy, low-cost solution with a 4-20mA output signal, and for situations where space is limited, such as in small, confined spaces in industrial equipment, or when the pressure measurement needs to be integrated into a smaller control system.

• PMP11: This model might be suitable for applications that require a low-cost, compact solution with a 4-20mA output signal, such as in smaller industrial equipment, or in control systems where space is limited.

The robust metallic sensor offers outstanding performance at low measuring ranges even at high static pressures in gas, liquid and vapour applications

Advantages

- Modular transmitter consisting of only three modules: electronic, sensor and housing

- Fast commissioning via Quick Setup menu

- Long-term stability

For more information, specific application advice or to order,

Please Contact us on +91 8367005552 or +91 9063008734

email: info@sigmaautomation.co.in or instsales@sigmaautomation.co.in

Technical Information for Deltabar S PMD75, FMD77, FMD78