Description

ACS 880 – 31/34 Low Harmonic Industrial Drive Module variable frequency drive

Low harmonic content, 3% Total Harmonic Distortion Current (THDI)

Due to the active supply unit and inbuilt line filter, regenerative drives are network friendly.

– vfd drive produces sinusoidal line current resulting in low network harmonics and lower losses in

power distribution.

– vfd drive reaches unity fundamental power factor, which increases the overall efficiency.

Unity power factor

– vfd Drive reaches unity power factor.

– helps in avoiding possible penalty charges from the power utility

– improves system efficiency reduces power consumption from grid

– enables more active power capacity in the network

– reduces heating of supply cables and other supply side components

– enables smaller cable sizes at grid side

– eliminates the need for compensation capacitors or active filters

Reactive Power Control

– can be used to compensate reactive power in the supply network. Requires external measurement and control circuitry

– Reducing reactive power helps to

• improve the power factor and system efficiency of vfd drive

• avoid penalty charges from electric utilities for excessive consumption of reactive power

• compensate reactive power without the need for additional capacitor banks or active filters

Optimizing Transformer sizing

– When using 6-pulse vfd drives, the transformer is selected using a factor of 1.35 x motor kVA to take into account power factor and harmonic distortion

– When using low harmonic drives the factor used is 1.1 x motor kVA. For example:

• Motor load = 1000 kVA

• 6-pulse system requires 1.35 MVA transformer

• Ultra-low harmonic solution requires only 1.1 MVA transformer

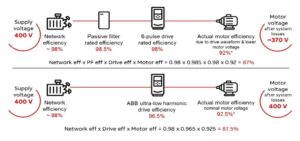

Immunity to network voltage variations

Ultra-low harmonic drives are able to stabilize the output voltage

– Active supply unit of the drive controls the DC voltage in order to guarantee full motor voltage even when the supply voltage is below nominal

– Secures reliable operation in weak networks

• ac drive can even compensate for fast variations in the line voltage

• No extra motor heating because there is no need to increase the motor current to stabilize the motor voltage*

Technical Details:

Input Voltage : 3 Phase. UN 380 to 415/SOO/690 V. +10% / -15%

Frequency : 50/60 Hz -5%

Power Factor : Cos O = 1 (fundamental)

Efficiency (at Nominal power) 97/c

Motor Connection

Voltage : 3 Phase from 0 to Supply Voltage

Frequency : 0 to ±593 Hz

Motor : Control Direct Torque Control (DTC)

Torque Control : Torque step rise time

Open Loop : <5 ms with nominal torque

Closed Loop : <5 ms with nominal torque

Non-linearity

Open Loop : 4 % with nominal torque

Closed Loop : 3% with nominal torque

Speed Control : Static accuracy:

Open Loop : 10% of motor nominal slip

Closed Loop : 0.01% of nominal speed

Dynamic accuracy

Open Loop : 0.3 to 0.4% seconds with 100% torque step

Closed Loop : 0.1 to 02% seconds with 100% torque step

Product Compliance

Machinery Directive 2006/42/EC. EN 61800-5-2:2007

EMC Directive 2004/108/EC. EN 61800-3: 2004 * Al: 2012

RoHS directive 20U/65/EU

Quality assurarxe system ISO 9001 and Environment system ISOl^COl

Waste electrical and electronic equipment directive (WEEE) 2002/96/EC

RoHS directive 2011/65/EU ULf EAC. RCM. UL. cUL TUV Nord (safety functions} CE

Environmental Limits:

Ambient Temperature Operation : -15 to *55 * C, No frost allowed, *40 ‘ C to *55 ‘ C with derating by 1% per 1

* C rise in temperature

Cooling Method : Dry Clean Air

Altitude : 0 to 100C n* without dealing and from 1000 m to 4000 m with derating by 1%/100 m

Relative Humidity 5 to 95%. No condensation Allowed

Degree of protection AC5880-34: ipso

Functional Safety Safe Torque Off (STO according to EN61800-5-2)

IEC 61508 ed2: SIL 3. IEC 6151L SIL 3 IEC 62061: SIL CL 3. EN ISO 13849-1: PL e Contamination Level No conductive dust allowed

operation: iec 60721-3-3. Class 3C2 (chemical gases). Class 3S2 (solid particles)

Click here for the brochure: Ultra-Low Harmonic Drives