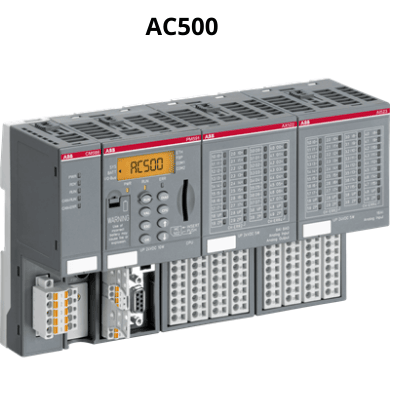

Description

ABB’s AC500-eCo is a range of scalable compact PLCs offering cost-effectiveness for modern industrial automation applications where small and flexible PLC solutions often represent the ideal solution.

Scalability

Save money by starting on a small scale – the flexibility of the AC500 platform enables you to scale up as and when needs dictate it.

ABB’s AC500-eCo has been designed to integrate seamlessly into the broader AC500 family, offering you the decisive benefit of having a fully scalable and modular system.

The AC500-eCo allows for individually customized solutions to be created by using S500 and S500-eCo I/O modules for small applications.

Additionally, for new AC500-eCo V3 PLCs, the already large amount of onboard I/Os can be extended using up to three option boards which add either more digital or analog channels or serial interfaces with or without isolation.

Therefore it will be easier to meet customers’ and application-specific requirements, reduce the footprint and save money.

The Automation Builder engineering suite available for the entire AC500 PLC range will save you time with easy configuration, many libraries, and function blocks for the most diverse customer-specific requirements.

Easy handling and flexibility

The user program can be downloaded via a memory card without the need for programming tools.

CPUs with integrated I/Os for small to large applications are available.

Motion I/Os allow you to realize simple point-to-point motion on up to 4 axes.

Pre-wiring is possible through the use of pluggable terminal blocks.

The modules can be mounted on the DIN rail with an easy-to-use snap-on mechanism.

The AC500-eCo is approved for customer use by accredited certification organizations around the world. This means the entire range can be deployed safely, reliably, and globally.

CPUs

Based on the successful AC500 range, the extremely compact AC500-eCo PLCs offer the most flexible and economical configuration available, low-cost and straightforward servicing, and all requirements of a modern control system from small to demanding applications.

- For over a decade, the AC500-eCo V2 has been a proven and reliable range of CPUs tested in the field, and it is well established on the market. AC500-eCo V2 will remain active for a few years in parallel with the new AC500-eCo V3.

- The new AC500-eCo V3 CPUs are based on the same concept and footprint as AC500-eCo V2. They enhance the range with larger memory, and more processing performance. The new CPUs provide more onboard I/O channels and more scalability via option boards which extends the feature set while maintaining the footprint. Additionally, they include various fieldbus communication capabilities and connectivity to cloud applications with secure protocols.

- ABB uses a standard IEC61131-3-based programming system for the entire AC500 family – you will be up and running in no time with Automation Builder engineering suite.

S500 – eCo – I/O Module

The scalability offered by the AC500-eCo gives you the assurance of knowing that the system is able to grow with your needs. We offer a wide range of digital and analog S500-eCo I/O modules for different applications.

- AC500-eCo V2 and AC500-eCo V3 Standard and Pro CPUs are centrally extendable with up to 10 I/O modules – standard S500 and/or S500-eCo modules can be mixed.

- The AC500-eCo is compatible with the AC500 PLC family – this provides you with the option to build customized solutions based on the standard S500 and S500-eCo I/O modules range.

- The user-configurable I/O system gives you the flexibility of being able to make decisions and modifications right up to the last minute.

Accessories

A broad set of accessories rounds off the benefits of the compact AC500-eCo range. ABB’s AC500-eCo offers a host of accessories enabling you to implement your application economically and in time. With the AC500-eCo Starter kits you can familiarize yourself with ABB’s AC500 PLC range and the engineering tool within a very short time.