Description

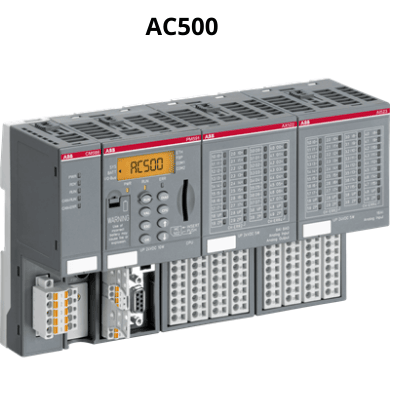

With the AC500 PLC range, we provide a reliable and powerful platform to design and create scalable, cost-effective, and flexible automation solutions.

Scalable

- The scalability of the AC500 PLCs is achieved by offering a large variety of devices to design and implement configurations suitable for simple control tasks or complex automation solutions.

- The AC500 PLC provides action flexibility with one integrated software.

Cost-effective

- The AC500 PLC range consists of various CPUs, I/O modules, communication modules, communication interface modules, and accessories.

- The “all modules used on any CPUs concept” in combination with our life cycle policy helps our customers to react quickly, flexibly, and economically to new requirements.

Flexible

- Our AC500 is designed to offer the needed easiness, security, and reliability to expand the automation system to new challenges.

- The memory, performance, and networking capabilities mean more functionality, advanced visualization, and more operating comfort – for even better individual customer solutions.

CPU’s

We build our AC500 CPUs to offer the needed easiness, security and reliability to adapt the automation solution to new coming up challenges.

Dynamic and adjustable interaction

- We design a broad range of fast processing CPUs with appropriate memory, performance and networking capabilities.

- The use of one integrated software in the entire AC500 PLC range provides the easiness to fulfil new demands.

Networking

- Our AC500 CPUs have a variety of communication possibilities, onboard and with expansion modules, which can be integrated into various combinations, forming great network nodes from smallest to largest automation solutions.

- These capabilities connect your automation solution to the past, keep it up to date and lead it into tomorrow.

- If you need reports, signals and messages anytime anywhere then use our built in web server (free of charge).

Applications

- The AC500 can be used in many different applications, for example, wind mills, solar trackers, high-volume circuit breaker production, large vessels, tunnel automation, traffic control, packaging, printing machines and robotics.

- Choose the AC500 platform and you can participate in our know-how on different applications and our software libraries (e.g. motion control, water, solar, drives).

Communication interface modules

We develop and implement various connectivity options for remote I/Os and distributed periphery in our AC500 PLC range.

- We offer a wide range of connectivity options for remote I/Os in our AC500 PLC range to keep your automation solution adapted to the past, connected to present day and prepared for tomorrow.

- In addition, our communication interface modules provide even more functionalities like fast counter and additional configurable I/Os.

- Our communication interface modules for distributed periphery provide a variety of connectivity which can be integrated into various combinations, forming great network nodes from smallest to largest automation solutions.

Supported communication standards and protocols are:

- EtherCAT

- PROFINET

- PROFIBUS DP

- CANopen

- Modbus TCP

- ABB CS31

S500 – I/O Module

We believe expanding or adding field devices should be quite simple. Therefore we develop multifunctional and software configurable I/O modules and provide numerous basic I/O modules with different channels, signal voltage and fieldbus connections.

You can choose and combine your needed type of connection:

- Central, using local I/O bus of CPU module.

- Up to ten I/O modules can be connected to the CPU.

- Decentralized periphery via fieldbus between CPU module and remote I/O modules.

- For each fieldbus slave, up to ten I/O modules can be connected.

- Multifunctional approach: some modules cover a broad range of requirements, e.g. AI531 with 8 types of different signals in one module.

Accessories

Within our AC500 platform, we build our AC500 devices to offer the needed easiness, security and reliability to adapt the automation solution to new challenges coming up. In addition, a range of complement accessories to adapt, combine and connect to the AC500 platform is available.

Conditional Monitoring CMS

Optimize your assets with a condition monitoring system (CMS) using the proven AC500 PLC platform. The FM502 module helps you to improve your operations resulting in greater efficiency and higher reliability while minimizing service and operating costs. Build dedicated stand-alone or control integrated CMS solutions with the modular AC500 PLC platform.

- Condition monitoring and fast protection (vibration, current, voltage, speed/encoder).

- FM502-CMS function module needs to be connected with terminal base TF5x1 for direct interfacing to CPU, communication modules, other I/O.

- PM592 CPU to be used on same TF5x1 (data storage, signal processing or communication, C-code interface for own diagnosis algorithms, 4GB flash disk for fingerprints, indicator trending).

FM502-CMS module

- 128 MB local user memory.

- 16 analog inputs, all synchronously sampled; configurable as IEPE or +-10V.

- Per channel 50k samples/s, 24bit ADC, per channel adjustable sampling, start, stop, trigger.

- Encoder inputs (5V or 24V) up to 300 kHz, 2 counters; 12 modes, including absolute SSI (1 MHz).

- Compact WAV files delivered automatically to CPU, including synchronized encoder signals.

- Input values always available for fast protection in CPU I/O image (also if no measurement is running).

- Included in Automation Builder: configuration, libraries for CMS control and WAV file handling.

- Download package: “Application examples” and signal processing library.