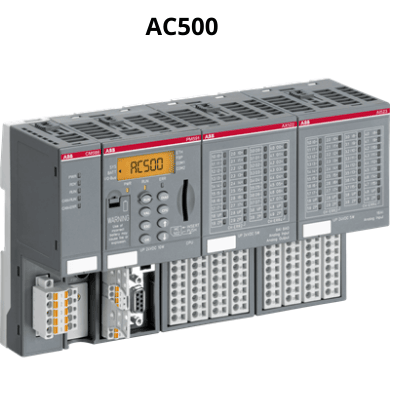

Description

We provide a reliable and powerful platform to design and create scalable, cost-effective and flexible automation solutions. Our platform should be functional and operational – even under rough environmental conditions. Therefore we develop the eXtreme Conditions versions.

The benefits from the AC500 PLC platform like one Automation Builder engineering suite, I/O modules, scalability and flexibility, high-performance communication, libraries, and web services are combined with resistance to

- High humidity

- Salt mist

- Vibration

- High altitude

- Hazardous gases

- Temperature: from -40 to + 70 °C.

The AC500-XC range replaces expensive cabinets by its built-in protection against dirt, water, gases and dust. Many traditional practices such as HVAC for the panel, shock absorbers, door sealing etc. are not required.

AC500-S Safety PLC range – extreme conditions XC modules

- Applicable for harsh environmental applications like crane, hoist, winch, robots, wind (offshore and onshore), solar etc.

- Physical dimensions, basic electrical characteristics and software compatibility correspond with the standard AC500-S version.

- Engineering and operations are much more cost-efficient since spending money on special cabinets and cabling practices can be avoided.

CPUs

We built in our AC500-XC the needed easiness, security and reliability to adapt your automation solution to new coming up challenges.

Dynamic and adjustable interaction

- Real time capabilities and high data transmission speed are just some of the demands for a control system.

- We design a wide range of fast processing eXtreme Conditions CPUs with appropriate main board, memory, performance and networking capabilities.

Networking

- Our AC500-XC CPUs have a variety of communication possibilities, onboard and with expansion modules, which can be integrated into various combinations, forming great network nodes from smallest to largest automation solutions.

- These capabilities connect your automation solution to the past, keep it up to date and lead it into tomorrow.

Applications

The AC500-XC CPU can be used in harsh environments like:

- Operating temperature -40ºC to +70ºC.

- Extended immunity to vibration (IEC61131-2/IEC60068-26).

- Extended immunity to hazardous gases (IEC60721-3.3 3C2) i.e. H2S, SO2/SO3, NOX.

- Extended immunity to salt mist (EN60068-2-52/ EN60068-2-11).

- High altitudes, operational up to 4000m above Sea Level or up to 620 hPA.

- Extended EMC requirements (EN61000-4-4 and EN61000-4-5).

- Shock resistance (IEC60068-2-27).

- Electrostatic Discharge up to 8 KV.

If you need reports, signals and messages anytime anywhere then use our built in web server (free of charge).

AC500-XC products carry the snow symbol.

Communication Module

We develop and implement various connectivity options for the control and field level of our AC500-XC PLC. This benefits our customers to keep their automation solution adapted to the past, connected to present-day and prepared for tomorrow.

The AC500-XC combines up to four CPU-integrated communication interfaces with additional (up to) four slots for communication modules.

These communication modules provide a variety of communication possibilities to the control and field levels and can be integrated into various combinations, forming great network nodes from smallest to largest automation solutions.

Supported communication standards and protocols are:

-

- PROFIBUS DP

- PROFINET

- Ethernet

- Modbus TCP

- CANopen

AC500-XC products carry the snow symbol.

Communication Interface Module

We develop and implement various connectivity options for remote I/Os and distributed periphery in our AC500-XC PLC range.

We offer a wide range of connectivity options for remote I/Os in our AC500-XC PLC range to keep your automation solution adapted to the past, connected to present day and prepared for tomorrow.

Our communication interface modules for distributed periphery provide a variety of connectivity which can be integrated into various combinations, forming great network nodes from smallest to largest automation solutions.

Supported communication standards and protocols are:

-

-

- PROFIBUS DP

- PROFINET

- CANopen

- ABB CS31

- Modbus TCP

-

AC500-XC products carry the snow symbol.

S500 I/O modules

We believe expanding or adding field devices should be quite simply. Therefore we develop multifunctional and software configurable I/O modules and provide numerous basic I/O modules with different channels, signal voltage and fieldbus connections.

- Central, using local I/O bus of CPU module.

- Up to ten I/O modules can be connected to the CPU.

- Decentralized periphery via fieldbus between CPU module and remote I/O modules.

- For each fieldbus slave, up to ten I/O modules can be connected.

- Multifunctional approach: some modules cover a broad range of requirements, e.g. AI531 with 8 types of different signals in one module.

Accessories

Accessories for eXtreme Conditions variants of the AC500 platform with extended operating temperature, immunity to vibration and hazardous gases, use at high altitudes and in humid conditions.